Home / Products> Graphite_products> Graphite_Electrode> Graphite Electrodes

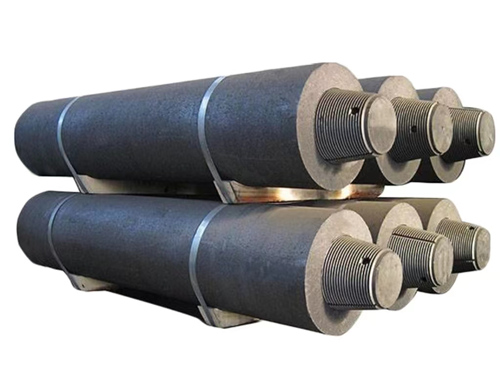

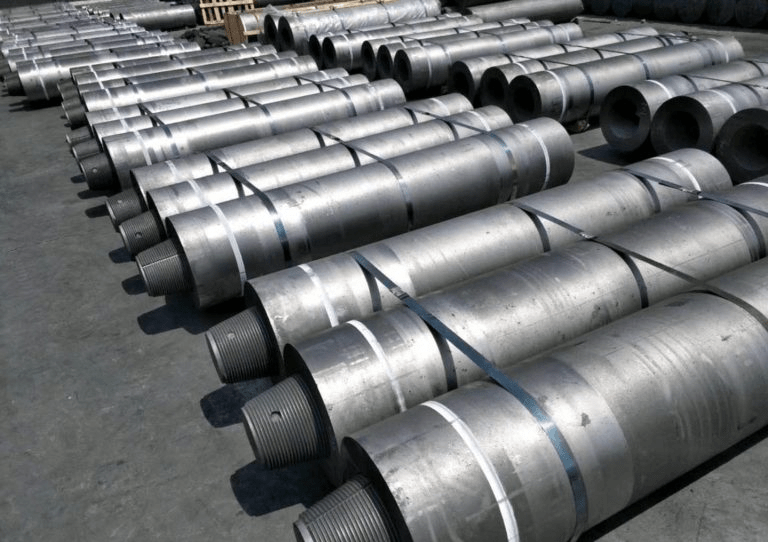

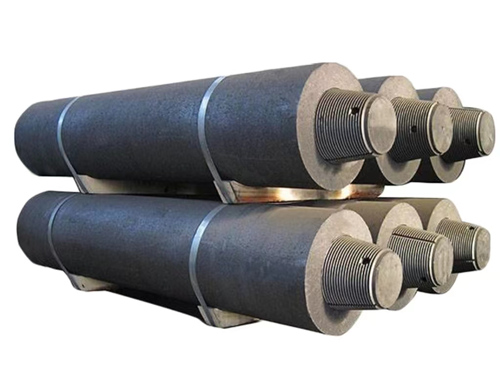

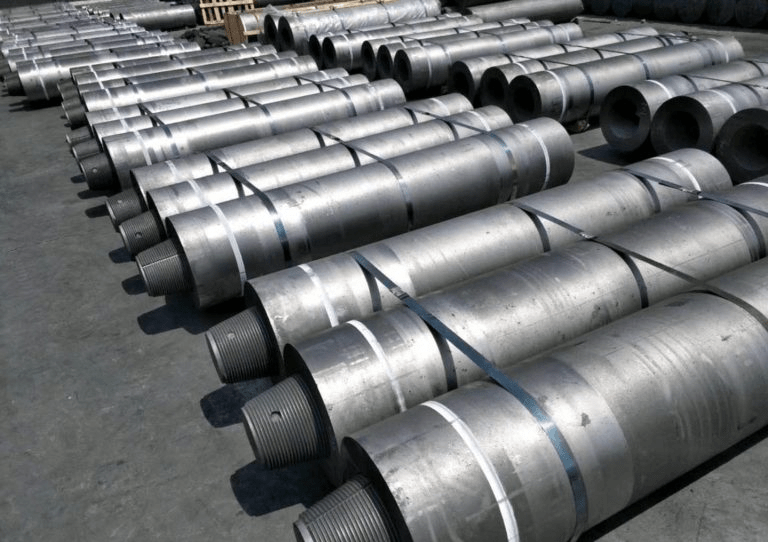

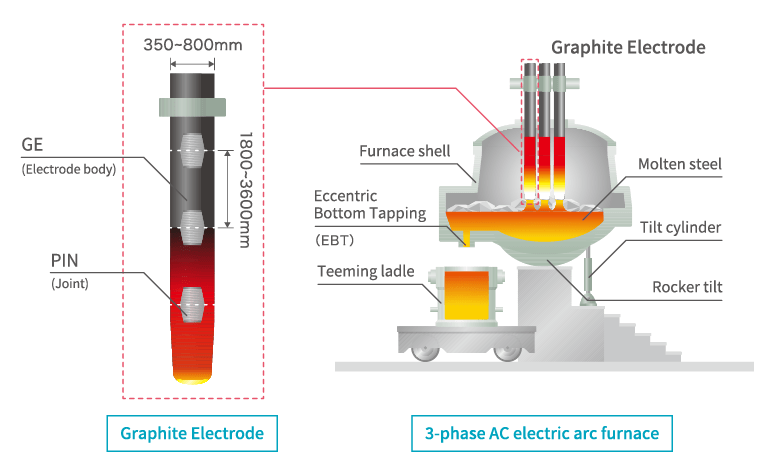

Graphite electrode, also known as artificial graphite electrode, is based on petroleum coke and needle coke as the main raw materials, and coal pitch as the binder.After calcining, grinding, mixing and kneading, extrusion forming, roasting, asphalt impregnation, graphitization, machining and other series.A high temperature resistant graphite conductive material produced by the process.

Graphite electrode is made from domestic first-class petroleum coke and high quality needle coke and are widely used in electric arc furnaces for the production of alloy steels, metal, and other nonmetallic materials, etc. The Graphite electrodes include regular power, high power, ultra-high power, and square electrodes. The range of diameters covers from 200mm to 700mm.

Graphite electrode has the advantages of low electrode consumption, fast processing speed, good processing performance, high processing precision, small thermal deformation, light weight, easy surface treatment, high temperature resistance, high processing temperature, electrode bonding and so on.

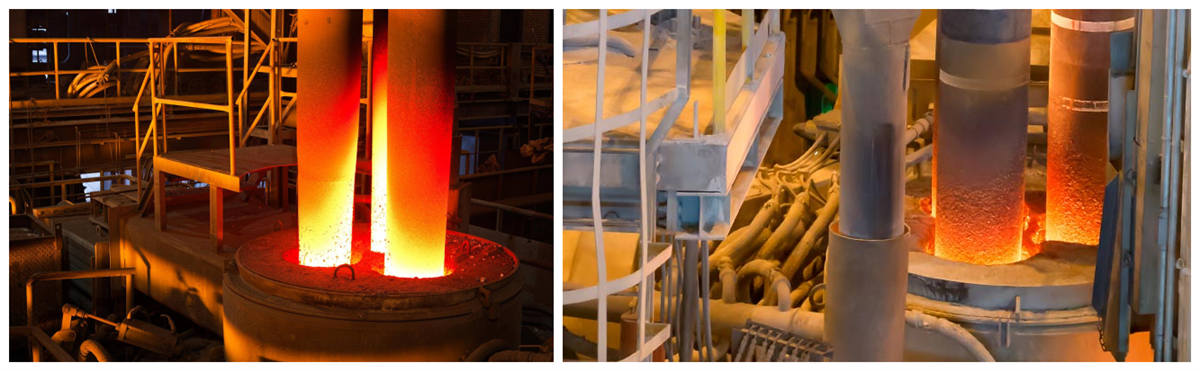

Graphite electrodes are mainly used in electric arc furnace steelmaking, the working principle of graphite electrodes in steel refining involves generating high temperatures through an electric arc, melting the metal at the furnace’s base, and facilitating critical chemical reactions such as decarburization and alloying to produce high-quality steel.

Technical Characteristics of Graphite Electrode RP, UHP:

Unit |

AC Furnace |

DC Furnace |

|||

350~450mm |

500~700mm |

550~800mm |

|||

Features |

RP |

UHP |

UHP |

UHP |

|

Bulk density |

g/cm3 |

1.58~1.70 |

1.65~1.76 |

1.66~1.74 |

1.68~1.75 |

Specific resistance |

μΩm |

6.0~8.5 |

4.5~6.5 |

4.5~6.5 |

4.2~5.5 |

Young's modulus |

kN/mm2 |

8~12 |

11~16 |

9~14 |

9~13 |

GPa |

8~12 |

11~16 |

9~14 |

9~13 |

|

kgf/mm2 |

800~1,200 |

1,100~1,650 |

950~1,400 |

900~1,300 |

|

Bending strength |

N/cm2 |

1,000~1,400 |

1,200~1,800 |

1,000~1,500 |

1,000~1,500 |

MPa |

10~14 |

12~18 |

10~15 |

10~15 |

|

kgf/cm2 |

100~140 |

120~180 |

100~150 |

100~150 |

|

Thermal expansion coefficient |

×10-6/゚C |

0.8~1.5 |

0.8~1.5 |

0.5~1.0 |

0.5~0.9 |

×10-6/゚F |

0.4~0.8 |

0.4~0.8 |

0.3~0.6 |

0.3~0.5 |

|

True density |

g/cm3 |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

Total porosity |

% |

23~29 |

20~26 |

21~26 |

20~25 |

Ash content |

% |

Less than 0.2 |

Less than 0.2 |

Less than 0.2 |

Less than 0.2 |

Please feel free to leave a message. We will reply you in 24 hours.

Info

Send Email

Wechat / Whatsapp

Company Tel

Company Fax

+86-15936223891

Submit Request